Please give us a bit of detail about your background.

My background is primarily in jewellery retail. I started from humble beginnings selling on shop floors and have progressed through to top national operations roles. I am very fortunate to have been able to travel with my roles throughout Australia and NZ, opening boutiques and setting up new businesses—at one stage I was responsible for over 600 staff. I have worked with some 170 shopping centres over the years, and most recently I was running one of Australia’s buying groups. There is little that I have not seen in the retail space.

I find working with the independent jewellery sector extremely rewarding, yet challenging compared to a corporate structure—the relationships and connections you make are really worthwhile and long-lasting. I have also been blessed to work alongside some of the world’s best manufacturers and jewellery brands. Now, being a part of the Pallion Group is an amazing opportunity and a perfect fit. It feels like I am home.

What has been the acceptance and adoption rate of CAD/CAM by jewellers in the past decade, and has it exceeded your expectations?

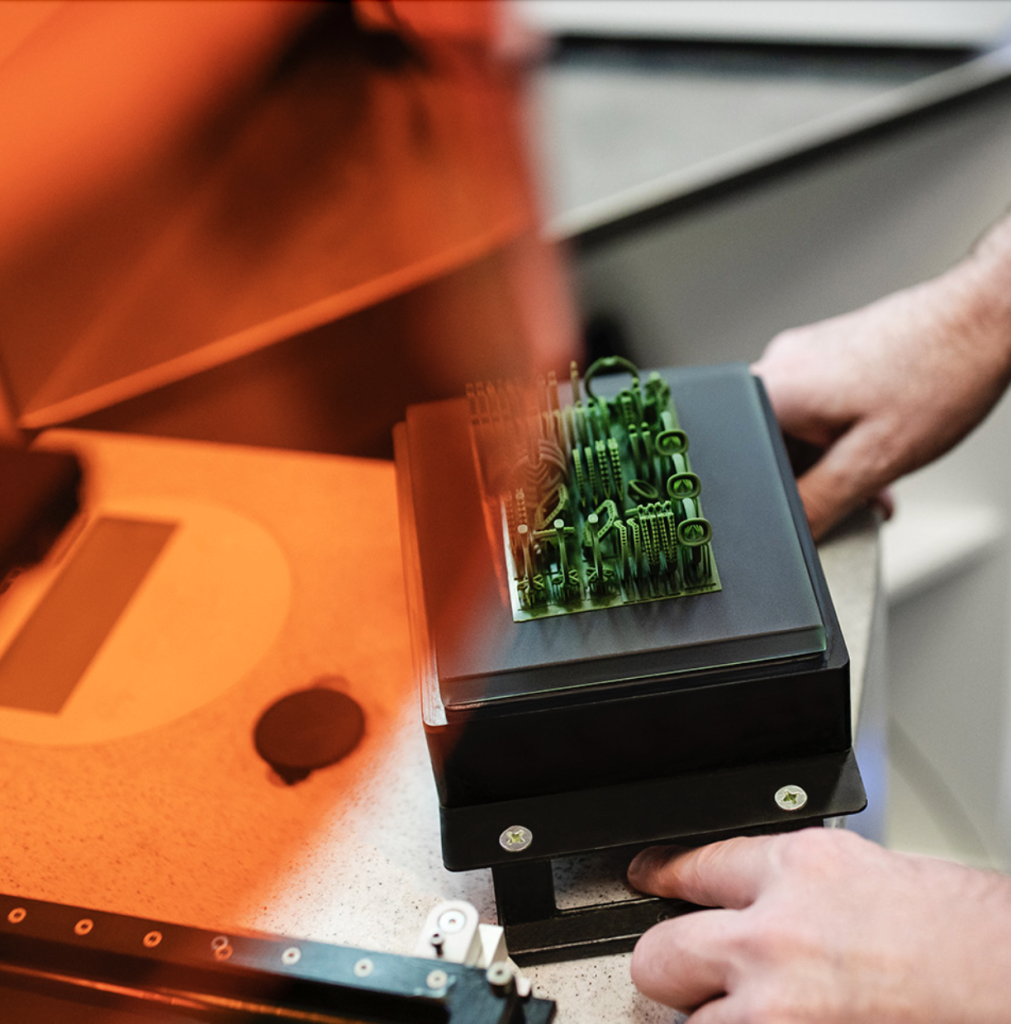

CAD/CAM is widely accepted nowadays. I had always expected the industry would embrace this technology, and that it was the only way forward. It just takes time for people to adapt, learn and embrace any new technologies. Environmental situations within our industry have really propelled CAD. I find that jewellers now utilise the benefits of CAD specific to their needs. There are some very exciting developments coming with CAD at Palloys—watch this space!

Do you agree that buying groups play an essential role in the jewellery industry?

They do play an essential role for their members and preferred suppliers however, a buying group is not for everyone. There are some brilliant jewellers and retailers who are passionately independent. There is room and potential success for all. The different resources the group offers for its members are going to be important to them. For some, it is no fees and better discounts, while for others, it may be website management. One thing is clear though, and this goes for all of us, as a buying group, supplier, wholesaler, or manufacturer, we all know the margins in jewellery are thinning substantially. The value you must provide to your customers has to be there or you will rapidly become irrelevant. Global conditions have greatly impacted the jewellery landscape and will continue to do so.

What are the greatest innovations in the jewellery industry over the last five years?

The biggest development in jewellery has been the lab-grown diamond. I brought these into Australia back in early 2018 and there is no doubt they are booming globally. Whatever you might think of them personally makes absolutely no difference to how the market has engaged with them internationally.

Moreover, the technological advancement in the lasering space is amazing and very much revolutionising processes within jewellery production.

Where do you see the Australian jewellery industry being in five years?

It is still heading in a direction consistent with our projections. There are fewer retail jewellers in the industry however, those who are succeeding have invested in their businesses and branding. Jewellery brands with an individual aesthetic and who customise work for their clients are currently doing great business.

Skill shortages are a real concern for jewellery. We are struggling to find quality workers who see their futures in the jewellery industry. This skills shortage is across all areas of the industry—bench jewellers, sales teams, marketing professionals and administrators. I know some boutiques that are so affected by this issue and its associated problems that they have downsized their business, so they no longer have the ongoing stress.

Jewellery is so resilient and it prospered during the COVID-19 pandemic. This was spurred on by the lack of international travel and a desire to purchase locally. Over the last few years, there were impressive results from the independent jewellers right through to the major chains. I do think the real challenge for jewellery is ahead, based on the current fragility of the global economy.

What are the benefits of working with Palloys for small and large jewellery companies?

People, Quality, Service and Supporting Australian-made.

Although Palloys is a massive business now, we know where we have come from and where we are going. We are a big part of the history of jewellery in Australia and our legacy depends on the jewellery businesses we service daily.

We are, foremost, an Australian manufacturing company and use 100 percent Australian Gold produced through our sister company, ABC Refinery. We create all our fabricated metal products in-house from 100 percent Australian gold for you, every day. Who can attest to that in our industry?

I think it is the scope of what Palloys can do for Australian jewellery businesses which is paramount. We can produce en masse or craft an individual item specific to your requirements. Our experienced team is world-class across refining, fabrication, CAD/CAM, finishing and personalisation.

Read below for related stories: