Sophie Kim – Creative Consultant, Palloys

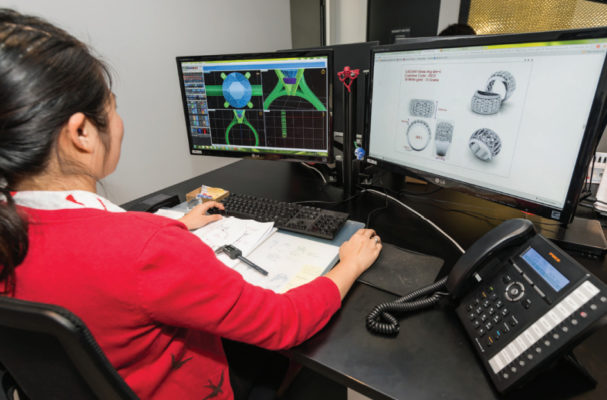

CAD, or computer-aided design, has truly revolutionised how we manufacture jewellery at Palloys. Its multi-faceted effects have enabled us to streamline and personalise the manufacturing process of a piece, from concept to customer. CAD has enabled jewellers to create magnificent designs with the most accurate precision, in a prompt manner.

The importance of computer-aided design is paramount in the current state of our jewellery industry. CAD enhances the product offering by giving the jeweller greater control over the design and manufacture of their designs.

That is the essence of what separates Palloys in the jewellery industry—our ability to take a client from their first design and guide them through the processes involved in bringing their piece to life, facilitated by the fact that every single process is undertaken exclusively in our workshop at Palloys, beginning with CAD. The wide uptake of CAD technology has illustrated the significance of creating specialised and accurate designs.

CAD at Palloys involves a wonderfully personalised, one-to-one consultation with our designers. The CAD team at Palloys is enriched with the sharp expertise of our staff. Each team member has over 10 years of experience CAD, or computer-aided design, has truly revolutionised how we manufacture jewellery at Palloys. Its multi-faceted effects have enabled us to streamline and personalise the manufacturing process of a piece, from concept to customer. CAD has enabled jewellers to create magnificent designs with the most accurate precision, in a prompt manner. PALLOYS POINTS Sophie Kim, Creative Consultant, Palloys Concept to Creation with CAD software, primarily in the speciality of jewellery design.

We are one of the largest CAD teams in the jewellery industry, and our communicative and positive work environment allows for a true forum of skills and styles that improves our team overall. This amalgamation of individual competency, teamwork and calibre of combined skill is unique to Palloys in the jewellery design sector. Our highly proficient designers have the advantage of overlooking the manufacturing process to achieve the highest quality of precision and intricate designs for the jewellers. The CAD team is supported by an unmatched print capacity. Palloys has invested in the most advanced printers and the team focuses on producing the highest resolution of resins and waxes which ensures there is no porosity and minimum breakaway during casting. Whether we receive a design brief or stereolithography (STL) files from clients, there is always a dialogue between designer and client that results in the creation of the final 3D rendering from which physical production of the piece begins.

This ensures that the client has significant input in their design and the final 3D render, thereby improving client satisfaction when the piece is finished. CAD itself is a competitive service. As we are equally well equipped for its complimentary service, CAM (Computer[1]Aided Manufacturing), Palloys’ service is rare in that we are enabled to oversee and streamline every step, from creating the 3D render to the 3D print of the final design.

Our precise control and strong interdepartmental communication skills, coupled with the lack of need for outsourcing, is drastically more cost-effective for both manufacturer and client and enables a much quicker turnaround from design to the finished piece. Moreover, Palloys is one of the most cutting[1]edge and current when it comes to both software and hardware. We are fastidious with ensuring all our programs have the newest and most advanced licensing and are functioning on the most recent updates. Our hardware is carefully quality-controlled and is regularly replaced with the newest models, ensuring we are equipped with the finest and most advanced technology in the industry. Our highly skilled Design & Print team is proficient in all major CAD applications, and we can work with your files created in MatrixGold, RhinoGold, 3Design and JewelCAD. We can work from a PDF, sketch, photo, or logo for the most streamlined and efficient CAD service. At Palloys, we want to educate you on the best techniques to create the most magnificent CAD designs. Having a start-to-finish approach to jewellery manufacturing, especially involving CAD, allows a more satisfied client, as well as a more fulfilling role as a creative consultant.

Having the ability to oversee a piece’s entire manufacturing journey is so rare, but even more unique to Palloys is how at the end, I get to experience the genuine joy and delight in a client when their completely custom design has been brought to life at Palloys. For the upcoming and new jewellers, we emphasise that it is essential to recognise CAD as an art form, customised to your own preferences. To be authentic, to learn and to observe and recognise your own signature style is the best way forward. This is the golden aspect of Palloys that make us a truly remarkable front-runner in the jewellery industry: our ability to take a concept to customer approach to each and every piece. Managing CAD as an aspect of this journey has been as challenging as it is gratifying.