PALLOYS POINTS

Chris Botha,

Operations Manager, Jewellery Division

Palloys

Post-production recycled material is already a reality within jewellery manufacturing. In the casting industry, many alloys must be reused and mixed at a 1:1 ratio in the next day’s production, technically making them at the most 50 percent recycled.

There is an assumption that the consumer market will associate ‘recycled’ precious metals with plastic saved from landfill and turned into new plastic bottles. In addition, it’s assumed that consumers will consider this a positive step because they sense it will protect the environment and create fewer new pollutants by reducing demand on the petrochemical industry.

But is this an accurate assessment? Gold will not typically make its way to landfill, so the plastic bottles analogy is flawed. Consumers have become more aware of the issues surrounding social responsibility but, in the case of precious metals recycling, the average punter is likely to confuse their ‘ethics’. Is recycling precious metals an environmental or a social ethics issue? Is there a difference and does it matter? And, more importantly, have we properly educated the consumer market in the distinctions? Interpretation is in the eye of the beholder and can be cleverly manipulated.

Post-consumer examined

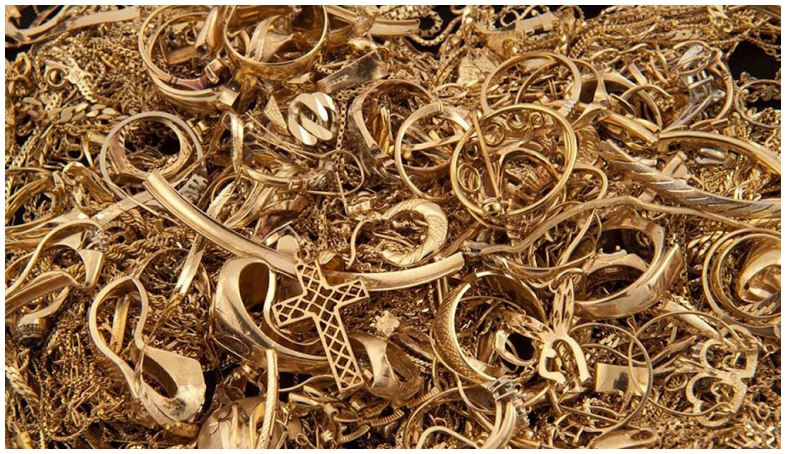

The process to guarantee 100 percent postconsumer material from an ethical angle has one fatal flaw. Before this ‘recycled’ metal makes it to refining, it will typically fall in the hands of second-hand buyers, but where did it come from before this?

Did it come from the same sources we refuse to work with due to their unethical trade practices or the same sources we refuse to work with because they fall in conflict mineral areas? As a disproportionately large percentage of this material will have its origin in volume jewellery production, with widely varying sourcing, the documented blockchain is limited, and the recycled metal in your ring may very well have originated from unethical sources, washed clean in a process to make it acceptable again.

Recycled gold: the logistics

When we examine the process of producing alloys, the ratio of fine material to base materials is an exact process. The purity of the base materials can significantly impact the durability, safety and workability of the material. For example, in the case of nine carat, the gram on your hand may have traceability to only 37.5 percent of its content. Does that make it only partially ethical?

Recycled alloys also reduce their construction each time they are melted; additives like zinc and copper will burn out of the alloy, requiring fresh material to be added to each melt, further diluting its “ethical” percentage.

More importantly, if we assume that just the fine material source is the crucial component, how do you prove its origins as ethical?

For jewellery, in the scope of this article, for material to be completely ethical you would need to prove the fine material came from a mine that is certified within Australia to guarantee ethical labour and procedures, then passed to an accredited refiner, audited for their labour and operations. This refiner will need to batch process only that material, not mixing it with any other source, then supply only that source to the alloy manufacturer, who similarly needs to carry accreditation for their practices proving that no other material was used in producing that alloy. Finally, it will go to a product manufacturer who must prove that only that particular alloy was used and no other alloy was mixed in production. The returned material will then go back to the front of that cycle to the refiner and begin all over again.

All Palloys precious metals, from casting to fabricated metals, are supplied by ABC Refinery. ABC Refinery produces investmentgrade bullion for several international banks, leading jewellery houses, royal families, religious institutions, car manufacturers and sporting events. Ethical sourcing is of upmost importance, and as a result, ABC Refinery is expected to document its precious metals supply. Complete transparency.

ABC Refinery is Australia’s only independent LBMA, SGE and COMEX accredited refinery. Today, ABC Refinery is the benchmark in Australian precious metal processing. It employs proprietary aqua regia, electrolytic chlorination and acidless separation (ALS) refining methodologies. ALS is the world’s most environmentally safe refining technology and produces no noxious residue. ABC Refinery is the only Australian refinery that employs this technology. In this way, Palloys is Australia’s only jewellery manufacturer that can trace its precious metal supply directly to its primary source.

Recycled or ethical?

The demand for fine materials for investment, global banking and jewellery will always far outstrip the material returned into the industry, so mining for the material will not decrease. The onus on the trade should be to ensure the sourcing of the product is ethical, the process to produce it is green and that the entire value chain is certified, with open traceability.

Any process is only as good as your ability to prove it exists and is legitimate.