Tantalum, often referred to as ‘black gold,’ has been gaining popularity in the jewellery industry due to its attractive, contemporary appearance. Its lustrous, dark grey colour gives it a sleek and modern look that makes it perfect for men’s wedding rings.

This tutorial will show you how to make a wedding ring with silver inlay.

To make this ring, you will need a section of 22mm outside diameter x 2mm thick tantalum tube. You can now buy 75mm sections of this tube from Jewellery Training Solutions. Check the JTS shop for availability.

Set your dividers to the required measurement, in this case 6mm, and scribe a cutting guideline around the tube.

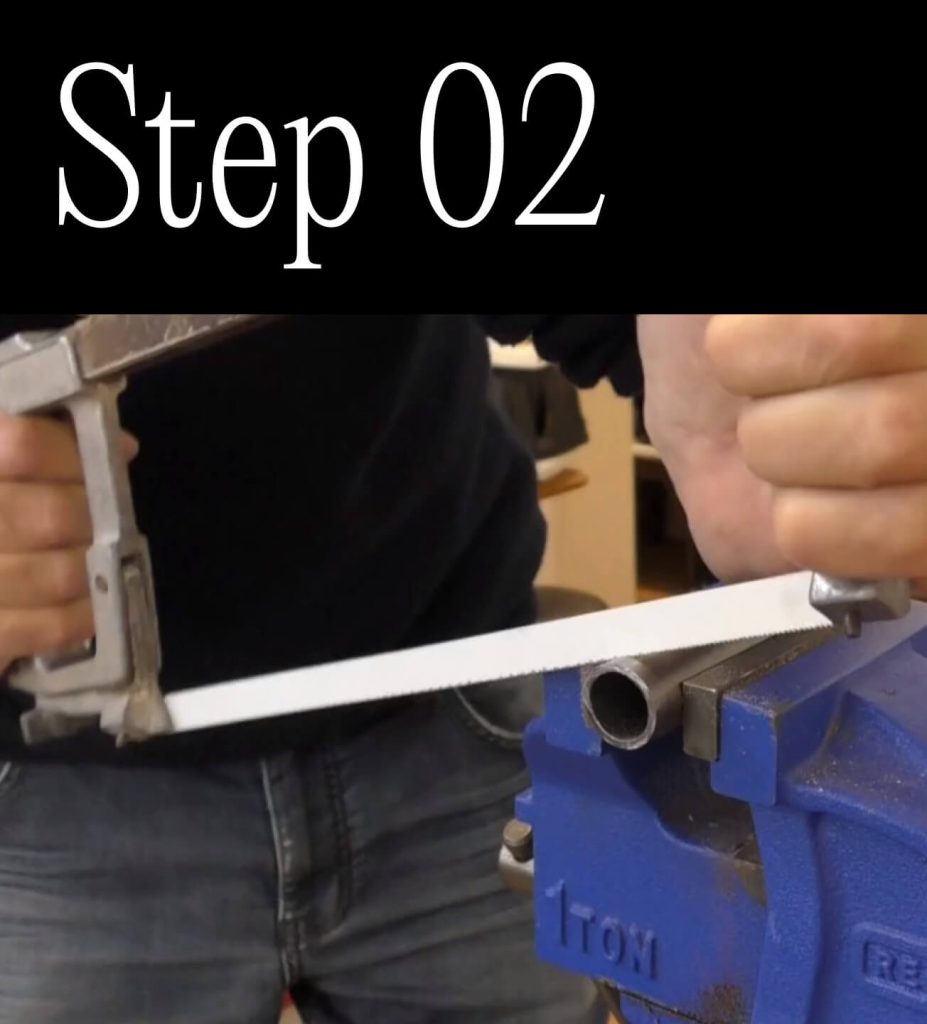

The most efficient way to cut off the section of the tube is with a hacksaw. I use a cobalt high-speed steel blade. Clamp the tube in your vice with the cutoff point in line with the vice jaw edge. You can then rest the blade against the side of the jaw as you cut around. Take your time as the blade can easily slide off the marking.

Do not try to cut in one direction only, keep turning the tube as you carefully cut to ensure you stay right on the line. You should end up with a ring with parallel sides.

File off the rough surface. The tantalum is ready-annealed and will not damage your files.

The finger size of the ring will be O½. Tantalum cold works surprisingly well due to its malleability, so you can stretch the ring to the finger size required either with a hammer and mandrel or with a ring stretcher. I’m making this ring size Q.

This design will have a silver strip inlaid along the centre of the ring. If you prefer a gold inlay or offset the inlay, use the same process.

First, cut around where the inlay is going with a 3/0 or 2/0 piercing saw blade. This will help to keep the hacksaw on track. The thickness of the hacksaw blade is 0.7mm, so this will be the channel width.

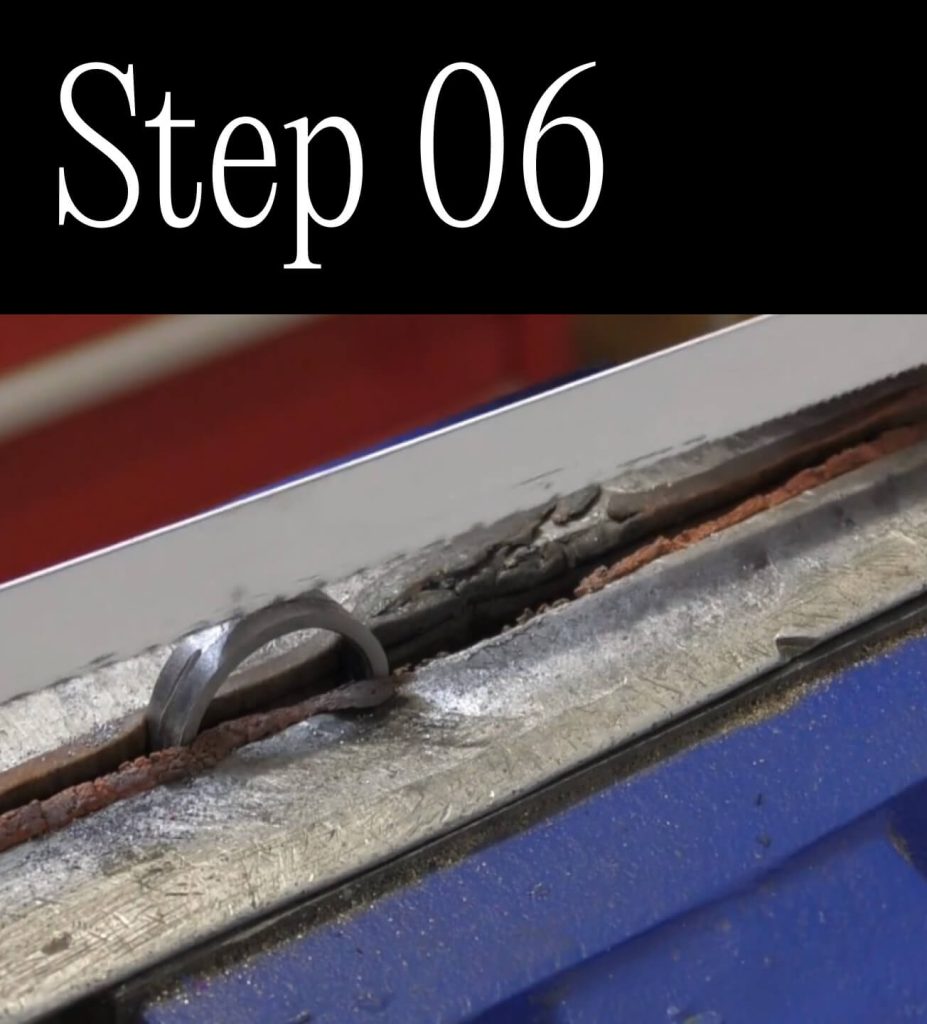

Clamp the ring into your vice. Carefully follow the piercing saw cut with the hacksaw blade. Use backward cuts only, until the blade has achieved enough depth to stay in the cut. Slowly and carefully turn the ring and keep cutting around as you go until you are back at the starting cut.

To ensure you have the correct channel depth all the way around, make sure that the hacksaw teeth are all the way into the channel when you check from a side view.

Now prepare a piece of square wire slightly larger than the channel width and square off the end.

Brace your mandrel in the vice and begin to tap the wire end into the channel. With a few firm taps, the wire should begin to grip into the channel. If not either file the wire a little or draw it down and try again. If the wire is too loose to start with, prepare another piece. Hammer the wire all the way around until it contacts the inlaid wire at the starting point.

Cut the overhanging inlay wire off, but make sure it’s not too short as it needs to fill the remaining gap. It also needs to be cut square to meet up correctly with the inlaid end.

Place the ring back onto the mandrel and tap the wire end into the remaining channel. You can now hammer the inlay more aggressively to ensure all the channel gaps are filled. Pay special attention to the inlay joint. It should be blended together and appear like a solid ring.

File the ring to the profile of your choice. This one has softened edges. If your technique was done correctly, there should be no gaps between the two metals.

Prepare the ring for polishing by going through the grades of emery paper up to 2000 grit. Use a steel polish such as Hyfin to finish the ring off. Alternatively, tumble finish your ring.

As you will see, tantalum has a beautiful lustre.

The contrast in colours looks amazing, but if you prefer a darker colour, heat the ring up to around 200°C. You may find that setting your kiln or kitchen oven to the exact temperature will give better results.

There’s more information and videos online.

For the video of this project go to jewellerytrainingsolutions.com.au/courses/tantalum-rings.

Check out the other courses and options; www.jewellerytrainingsolutions.com.au.

Further reading: