The Palloys difference lies in our commitment to excellence and exceptional jewellery production and manufacturing quality. With our industry-leading 3D scanning capabilities, state-of-the-art laser cutting services, and best-in-class CAD expertise, Palloys offers innovative solutions to superior jewellery production and a comprehensive suite of services that make us leaders in the industry. Additionally, our refining services, expert guidance, and extensive range of findings showcase our dedication to customer satisfaction. Chris Botha, operations manager of the jewellery division, explains the Palloys difference and why Palloys is your destination for all your jewellery needs.

What type of materials does Palloys use in its process, and what is the advantage of using fresh gold for manufacturing?

At Palloys, we rely on our extensive team capability to strike the perfect balance between fresh and recycled alloy for each cast or fabricated metal solution. We take pride in sourcing our materials exclusively from 100 percent Australian gold and silver, guaranteeing that every tree we cast and every piece of fabricated metal we produce reflects this commitment to quality.

The advantage of using fresh gold lies in achieving correct purity. Essential for maintaining consistent colour, strength, and fabrication properties. Palloys meticulously monitors our alloy composition ensuring we retain the greatest control over elements such as grain structure, key to successful fabrication and casting.

Palloys process, testing and quality controls ensure the highest alloy quality, resulting in finished jewellery of the highest quality, consistently exceeding your client’s expectations.

How does Palloys ensure that its Platinum and Palladium are high-density and porosity free?

Palloys platinum and palladium are high-density and porosity free by using our advanced casting processes and equipment technology. Our casting incorporates vibration technology and electronic stirring, which eliminates the formation of voids during the casting process. This, along with additional innovative techniques, results in a very fine porosity-free grain structure resulting in exceptional Platinum and Palladium castings.

How quickly can Palloys complete the print-to-cast process?

At Palloys, the print-to-cast turnaround time is two to three days. If a drawing is provided before 3 pm on a business day, a typical wax print will be ready to ship the next day. Stay tuned for Palloys’ same-day print to cast coming soon.

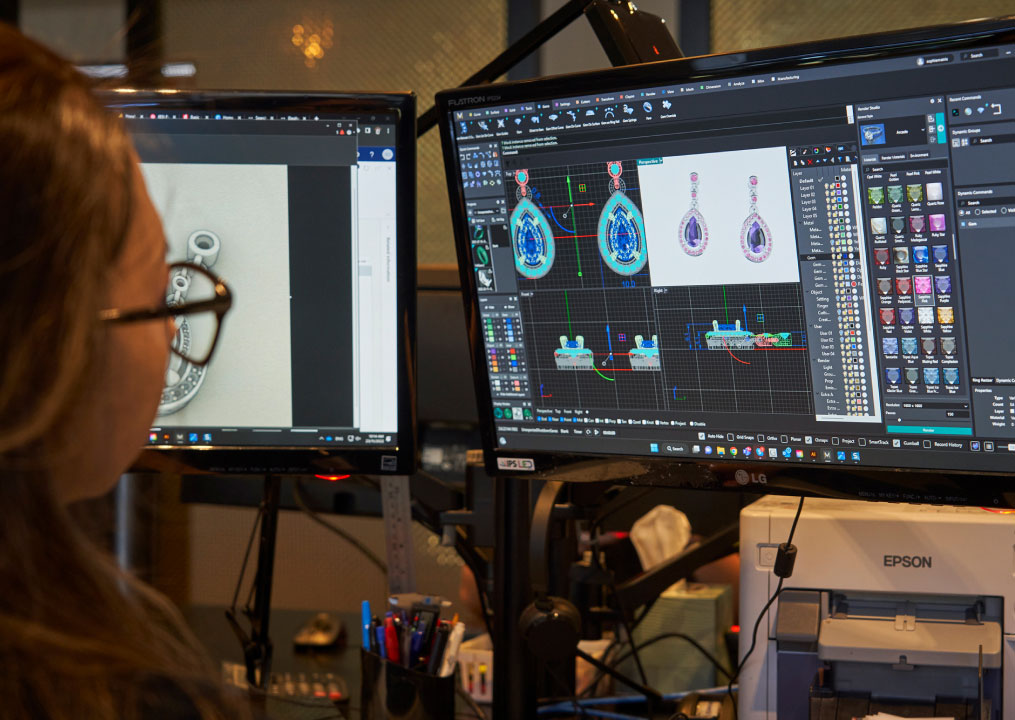

Why are Palloys’ CAD capabilities considered best in class?

Palloys’ CAD team is one of the largest in the industry, with highly skilled qualified designers with over ten years of CAD experience. We offer personalised one-on-one consultations to our clients. Supported by advanced printers, Palloys ensures high-resolution resins and waxes, minimising porosity, and breakaway during casting. Our end-to-end service, cutting-edge technology, and streamlined service contribute to cost-effectiveness and quicker turnaround times, establishing Palloys as a leader in the jewellery industry.

Why should customers choose Palloys for their jewellery production needs? What additional benefits does Palloys offer, apart from manufacturing services?

What sets us apart at Palloys is the fact that we offer Australia’s premier complete jewellery production service. Our domestic and international facilities produce superior quality finished jewellery pieces, including set stones, in less than 14 working days from sketch to finish. Our experienced team takes pride in providing expert advice and guidance to our valued clients, drawing on over 70 years of industry experience to offer valuable insights for informed decisions. Additionally, our extensive range of findings and charms is among the largest in Australia, showcasing high-quality options. We back our commitment to customer satisfaction with the Palloys Price Promise, guaranteeing competitive pricing, and our quality guarantee ensures that our clients receive exceptional and reliable jewellery.

Chris Botha

Operations Manager

Further reading: