1.

At Villani Jewellers, Michael Villani has a passion for providing customers with the highest quality jewellery. Their team specialises in custom creation and restoration, treating every piece of jewellery as if it were their own family heirloom.

Michael’s journey into jewellery making was borne at university.

“I was first exposed to jewellery making while studying industrial design at uni,” he says. “After completing a couple of courses which involved designing, problem solving and creating, I was hooked.”

Michael’s exquisite craftsmanship skills were cultivated in jewellers across Adelaide.

“I learnt the fundamentals at J&C Manufacturing Jewellers in Semaphore, South Australia and furthered my skills and knowledge in manufacturing at McIntosh Jewellers in the Adelaide Arcade,” he says. “Both places laid a foundation and skills that contribute to the beautiful pieces that I’m privileged to make today.”

In terms of technologies, Michael calls the microscope and power assist for stone setting a ‘game changer’.

“It’s taken my stone skills setting to a new level being able to see easily and to be super precise,” he explains.

Michael’s favourite material to work with? 18 carat yellow gold.

“It’s really malleable; beautiful to hammer, shape and file,” he says. “The rich lustre after a final polish is very alluring still to this day.”

For other jewellers frustrated with switching between safety and clear vision, Michael’s DIY secret is a saviour.

“I modified my visor to accommodate a welding lens while still being able to use the magnification. It flips up and down so I can use it when needed, saving a lot of time and frustration,” he says.

When asked what the most rewarding part of the role is, Michael points to creative thinking, the challenge of manufacturing and ultimately customer satisfaction.

“The fruition of creating an aesthetically pleasing piece of jewellery to a high standard that can be worn and loved for generations to come is quite special,” he explains.

And for the next generation of jewellery makers, Michael offers the following advice.

“It takes time to learn the fundamentals so be patient and don’t rush,” he says. “ It’s much more important to be accurate than fast at the start. Speed will come with time.”

2.

Harry Rose opened the doors to Harry Rose Jewellery in Canberra in 2009. Known for his bespoke pieces and the reimagination of older pieces into new and adored, everything is handmade in his studio, customised to suit his clients’ requirements.

Harry’s favourite material to work with?

“Platinum, it’s got a long memory so if you treat it with respect, it will give you the results,” he says.

Unsurprisingly, Harry’s favourite technique is fusing platinum, which he learned through trial and error.

Harry initially learnt basic makes and repairs early on in his career with an apprenticeship he held locally in Canberra. He later honed his skills in London where, as a production jeweller for 12 months, he was able to focus on bringing his finishing work up to standard as well as learning the benefits of planning a job before starting it.

Harry’s DIY secrets?

“Most of the time you can melt it down and start again, so don’t be afraid to have a go,” he says.

Harry’s much loved workbench includes his saw blade. This he uses for marking out, filling, à jour work, shaping claws and sawing.

For budding young jewellers considering a career at the bench, Harry explains his top tip. “Don’t bad mouth people and pay your bills promptly.”

3.

Christopher Hannan, of Hannan Jewellery Designs, specialises in custom engagement and wedding rings. Chris handmade his bench, using Tasmanian oak, with a design in mind to allow easy access to most of his tools.

“I’ve built my workbench to work for me. It includes custom storage so that every tool has a place. It has a built-in draw bench, under bench lighting and a vertical tool drawer. My favourite feature is the bur and drill holder that pulls out on a soft close drawer slide when I need access,” he says.

Chris started his apprenticeship in jewellery making in Western Victoria and later completed it and sharpened his skills under the tutourage of Alex Bauer in Fitzroy.

Chris’ most beloved tools are the old classics and Australian made tools due to the quality.

“My R. Simpson ring bender from the early 1960’s is just a joy to use. I’ve wanted one for a long time and finally got my own earlier this year. It always brings a smile to my face. I also adore my Tappa Tools mandrel which is new but made locally in Sydney by the very talented Fred Evenhuis,” says Chris.

In terms of technique, Chris suggests to fuse joins whenever you can.

“When you fuse the joint there are no concerns about solder joints from a resize showing up during the polishing process, and it also leaves the metal uncontaminated by solder,” he says.

Chris’ advice for those learning jewellery manufacturing?

“90% of making jewellery is how you hold things,” he says. “Whether you are filing, saw piercing or soldering, having the correct tools and technique with how you grip the piece you’re working on is often the difference between a good result and a great result.”

4.

At EverettBrookes, Ian Brookes and David Everett combine creativity and technical proficiency to create handmade, custom jewellery at their retail store in the Adelaide CBD.

Ian initially learnt his jewellery making skills under Sue Lorraine, the head of the JamFactory metal studio. David acquired his knowledge during his apprenticeship at Bell & Brunt under senior jeweller, Tony Causley.

“My favourite manufacturing tool is the Fretz chasing hammer,” says Ian. “I use it not for its intended purpose but for sizing rings and forging metals – I love the weight, shape of the handle and feel of the tool.”

David has a different style. He has always liked using the measuring gauge however, recently he has found himself reaching more for his magnifier to fine tune every detail.

When asked about any new technologies that they were slow to introduce but now can’t live without, the consensus among the two of them was clear. The puk-welder and laser welder.

“I was slow to take to both,” says Ian. “But now I’m an expert and find myself teaching the other staff how to use them.”

David shared similar initial thoughts however now calls them both “the greatest inventions”.

In terms of DIY secrets, Ian takes on a practical approach, while David is more cerebral.

“Keep a loupe on a retractable keychain at your work bench, so that’s always handy,” says Ian. “I also keep a magnet on my leather bench skin to keep broken blades together.”

David’s advice considers your mindset.

“Everyone has the capacity to learn to make jewellery if that is their goal,” he explains. “My best secret would be to overcome your own mental barrier and unlock your own potential.”

Ian and David use an array of skills learned during their apprenticeships and from private tuition. When manufacturing, Ian enjoys soldering and assembling where “all the components come together to create a thing of beauty,” while David’s favourite technique is manipulating/bending metal, sculpturing it, to create something unique.

5.

Michael Mooney of Serpent Cove Jewellery, specialises in solid signet rings and creating new, distinct designs. His bespoke engagement and wedding rings often use unique stones and have a customer made, one-off quality.

“I studied jewellery in high school and got an apprenticeship in Wagga. I learned on the job, taught by Paul Lucas and Troy Watkins, combined with coming to Tafe in Sydney for a week each month for three years,” says Michael.

Included on Michael’s manufacturing bench is his most loved tool, the micro motor.

“I got it at a silent auction at Tafe when I was an apprentice and I have used it ever since,” he says.

A technology that he was much slower to introduce to his work was CAD due to having something of a struggle with computers. However, Michael now has an appreciation for the precision the technology affords and loves the perfection it provides.

As with the above technology, Michael didn’t take to his favourite manufacturing technique straight off the bat.

“Wax carving was something at the beginning I was terrible at but I have stuck with it and have slowly got better over the years, and I now feel really competent with it,” he says.

With regards to materials to work with, Michael loves 18 carat yellow gold.

“It feels very ancient and is very pure. I love the transition when you heat it from frosty to when you polish it and its beautiful lustre,” he says.

For up and coming jewellers, new to the art of jewellery manufacturing, Michael offers a piece of advice.

“Never get disheartened by the work you see. Even the Mona Lisa was started with one stroke. It takes a while to build these skills – just make sure you build them right.”

6.

Michael Robinson, of David and Michael Robinson, the twins and creative team behind David Michael Jewels, enjoys meticulously handcrafting their ornate designs together from their workshop in Queensland. Both self taught, the brothers learned through doing, trial and error.

“I have a very simple jeweller’s hacksaw made by the artist Seth Gould,” says Michael, when asked about his favourite tool. “It’s traditional in its design but he hand forged it. It’s made exactly the same way that we make our jewellery (by a singular person’s hand) and I appreciate that I know exactly where it was made and how it was made. While using and appreciating it I often find myself hoping that my work finds an audience that appreciates the creations for exactly the same reasons as to why I love the saw,” he says.

Michael uses an array of self taught skills to bring their designs to life, and respects the forging part of the process the most due to the simplicity and hands on nature of the action.

“The fact that our minds have the technology to tell the muscles in our arm to exert a sudden blow in such a detailed and precise way is amazing,” he explains. “Watching a flat sheet of metal become whatever shape I want by hitting it in a certain way will never get old to me. Feels like a superpower. Hitting things with objects is an inbuilt skill we all learn as toddlers so I say that’s when I learned.”

Watching what was previously just a vision in his mind, Michael finds the transition from idea into something tangible to be the most satisfying part of his role.

“It’s like one day the concept is just a few electrical brain waves that might have been echoing around in my mind for years, then at the end of each day you get to see those concepts become reality. It’s very rewarding,” he says.

For those considering a similar career path, Michael offers some insight.

“Ask yourself why jewellery? What do you love about it, then focus on that element,” he explains. “Making things properly takes a lot of time so you need to really love it. If you don’t, there are plenty of other areas in the industry to focus on.”

7.

Martin Rogers Jewellery creates custom designs, made to last for generations. Andrew Mitchell, head jeweller and director at Martin Rogers Jewellery, is a big proponent of learning everywhere you can and not rushing to get to the next step.

“Things will go wrong more often than not at first, but don’t let it discourage you,” he says. “Keep photos of everything you make that you’re happy with, you will enjoy looking back at them.”

Andrew completed his apprenticeship with Gerard Ryan, and he and Donna Coutts contributed to Andrew’s broad foundation of skills which have been built on and refined with Martin Farkas.

“Every jeweller I’ve worked with at any level has added bits and pieces here and there and I’m a firm believer that you never stop learning,” he says.

One setting technique that he learned from Martin Farkas is a ‘honeycomb’ style of pavé.

“It’s one of Martin’s signature styles. I’d always loved it so was very excited to learn how to do it,” says Andrew.

In regards to manufacturing tools, in addition to being his most loved, Andrew’s favourites also carry sentimental value.

“I have two favourite tools. One is my Simpson ring mandrel and the other is an old hammer. The ring mandrel I’ve probably owned for 20 years and since Ron Simpson is no longer with us, it’s a bit of an irreplaceable object for me,” he says. “The hammer I haven’t owned at all, it’s Martin’s, but it’s the best balanced most useful hammer I’ve ever used and I’ve long dreamed of stealing it. Unfortunately, he just gifted it to our apprentice but I still have hope!”

When asked what the most rewarding part of the role is, Andrew comments on the connections between families and loved ones.

“Knowing that the things we make become part of family histories, and treasured by the owners in a way gives us a bit of immortality,” he says. “To be part of occasions that mean so much to people is often an emotional and beautiful thing.”

8.

Bob Bell, owner and operator of Plumeria Designs, creates bespoke jewellery, enjoying experimenting with different materials and keeping up with developing trends and innovations.

Bob’s journey into the jewellery industry started at Tafe.

“I did an art history course that had a module with jewellery manufacturing in it so I could learn the basics of the trade,” he says. “I was then lucky enough to land an apprenticeship with EverettBrookes.”

Before opening Plumeria Designs, Bob worked on the Gold Coast, learning a broad range of different skills, from the most basic repairs to creating stunning and intricate coloured diamond pieces.

“My favourite manufacturing technique is getting the perfectly straight wire for settings,” says Bob. “I was watching my colleague Ben make a six claw wire setting and his technique using the back of his diamond tweezers to roll the slight bow out of each wire. I’ve used this every time ever since.”

And Bob’s favourite tool?

“They’re all equally useful with my day to day but if I was to pick one on functionality it would be my Benchmate as it has a multi-purpose use from precision cutting to setting,” he says.

The most rewarding part of jewellery making for Bob is seeing the reaction from his customers.

“To be part of the process that marks a special occasion is something I find awesome but making something that gives the customer happy tears – Nothing beats that!” says Bob.

For jewellery manufacturers starting in the field, Bob is generous with his top tips.

“Make as many friends as possible in the industry as they’re great people and you can learn multiple techniques from everyone. (There is more than one way to make a ring!)” he says.

“Also, try all aspects of the industry: setting, engraving, wax carving, repairs, custom made, CAD,” he offers. “ Having the extra skills, even if it’s just the basics, will set you up for bigger successes later and if you’re in a pickle with a job you can figure out a way to fix it.”

9.

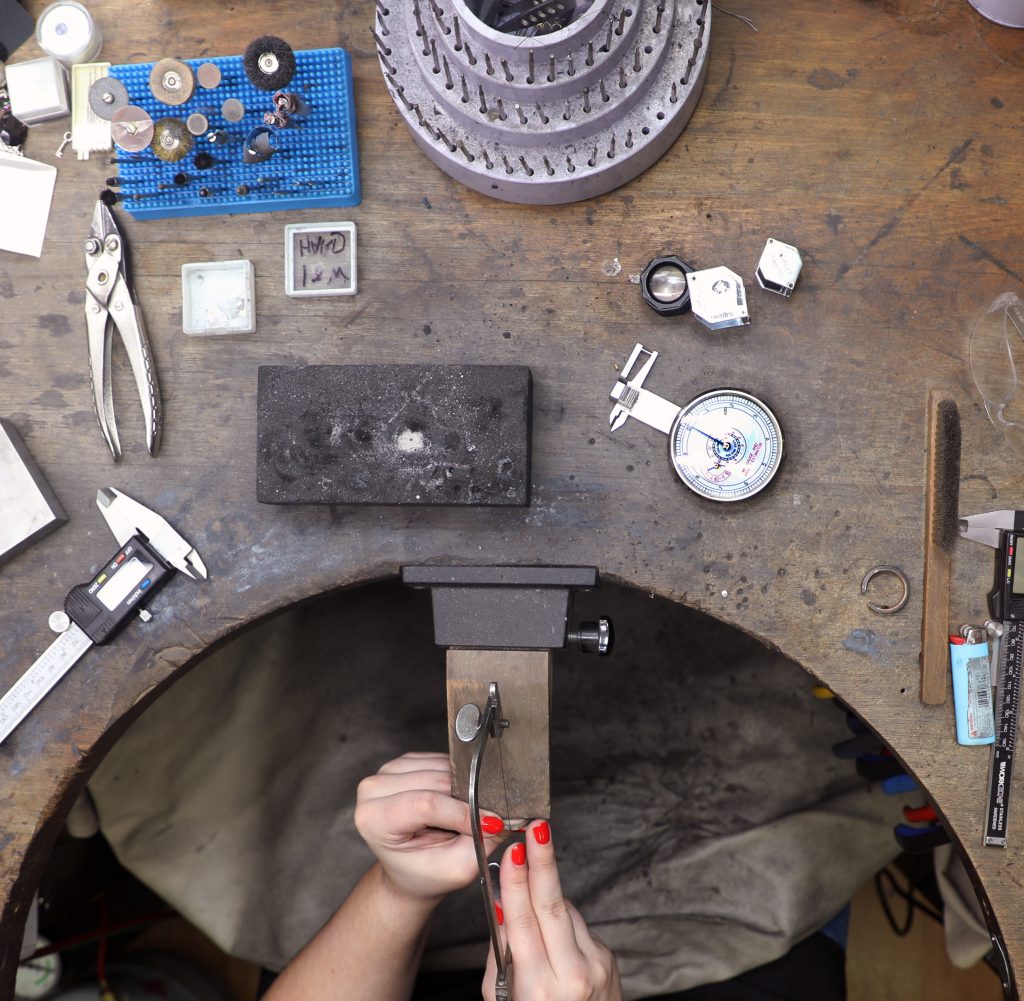

William Holland Whiting (Bill), owner and manufacturer at Archer & Holland Jewellers, has been hand making and repairing jewellery for over 50 years. His grandfather, Herbert Holland, started the business in 1918 and since then Archer & Holland has been family owned and operated for over 100 years. Bill is the third generation jeweller at Archer & Holland and his daughter Kate, who also works in the business as a diamond grader, is the fourth generation.

As a master jeweller, Bill’s special talent is making fine jewellery with precious coloured stones and diamonds.

“I enjoy seeing it transform from a solid block of gold or platinum to a treasured family heirloom,” he says.

Bill is passionate and creative and really enjoys losing himself in the process of bringing a customer’s dream piece to reality.

“My favourite technique is remodelling old worn family heirlooms back to life so they can live on and be safely worn again,” says Bill.

For jewellers just starting a career in manufacturing, Bill’s advice is to find your unique self in the art of making.

“You may be taught a certain way to do things but as you progress stay true to your style. That can’t be taught!” he says.

10.

Bell & Brunt has been making custom, handmade jewellery in Adelaide since 1920. Their specialty is unique wedding and engagement rings, as well as a passion for personal connection, established through customer service.

Learning in house from Bell & Brunt’s master jeweller Ben Shore, Abby Mills discusses the most rewarding part of her role.

“Creating heirlooms that will be part of someone’s story for their lifetime and hopefully generations to come,” she says. “There are not many industries where you can say you have had that kind of subtle but meaningful direct impact on people’s lives.”

Abby’s favourite manufacturing technique is setting stones, as she enjoys the satisfaction of seeing the process through from start to finish. Unsurprisingly, her preferred material to work with are the coloured gemstones (“the bigger the better!”)

For budding jewellery makers, Abby suggests forging your own path.

“Your career as a jeweller is not a straight line. Your path will be different from others,” she says. “Try not to compare yourself and stay focused on your own journey.”

With 35 years of experience, master jeweller Benjamin Shore has been learning the art of jewellery making since beginning his apprenticeship at 16 years old. Taught by P.A Edwards and John Heller, Ben enjoys old-school techniques and finds the most rewarding part of the role to be bending metal into an exact shape.

“My most loved tool is a tool that I made myself,” he says. “It’s a pair of dividers that I welded to a steel block.”

For up and coming jewellers, Ben’s top tip is all about accuracy.

“Precision!” he says. “More important than anything else.”

Gary Martin, another experienced jeweller, who recently completed 40 years in the industry, also began his career at 16.

Gary suggests the best thing for newcomers to the trade is practise.

“Practise and patience,” he says. “It takes time. It’s important not to get disheartened when learning.”

The part of the role Gary finds enriching is making jewellery from raw materials.

“My favourite manufacturing technique is hand making settings,” he explains, “which I learnt from Max T Langley.”

Similar to Ben, the tools at the workbench Gary reaches for the most are those that assist with accuracy.

“My most loved tools are dividers, which I use to make all settings very accurate,” he says. “And I can’t live without the laser welder and engraver.”

Taught initially by Jacques Fabien and then by the master jewellers of Bell & Brunt, James Young also can’t live without the laser welder. However, when asked his favourite manufacturing technique, James provides a different answer.

“Creating the fancy back holes of a channel set band,” he explains. “It’s satisfying to do and different every time.”

James’ workbench includes a charcoal block that always has a flat edge as well as his most loved tool, the dividers sharp (and always dialled in!)

“The craft takes time,” he explains. “The skills don’t happen overnight. Enjoy success and learn from the mistakes.”