It’s been a tough year for every industry, and manufacturing jewellery is no exception, with lockdowns, travel restrictions, less consumer disposable income/confidence and postponed or cancelled trade fairs all making life difficult for the manufacturing jewellery just trying to make ends meet. Here we chat to seven major players in the Australian and New Zealand manufacturing jewellery industry to find how they’re coping.

Business confidence down, but not out

While the majority of our respondents reported sluggish sales and unpredictable business since the pandemic broke out, fortunately it hasn’t all been bad news. Brett Low is a Gold Coast-based sole trader jewellery designer and manufacturer at Deer Honey Jewellery who specialises in one-off custom designs, and he reported seeing a lot of interest in custommade jewellery, remodelling and repairs. “Talking to my jeweller friends in the local area, they are also finding business to be strong,” he said. “I think we are all a little surprised but certainly not complaining.”

Across the Tasman Sea, New Zealand has had to contend with what some may consider draconian restrictions which is stifling business, but there is a silver lining for some of our Kiwi cousins in the jewellery industry. Solar Jewellery is an Auckland-based jewellery designer, manufacturer and wholesaler, and managing director Roland Plank said that until COVID hit, Solar Jewellery was going great and ahead of budget.

“The lockdown beginning end of March of 6 weeks did put a dent but we have been able to get back on track and have just finished our end of financial year July slightly ahead of last year,” he said.

Worth & Douglas is one of Australasia’s leading wedding ring manufacturers based in Victoria and Auckland, and despite having an unpredictable business environment, Business Development Manager Chris Worth said the business had a busy June and July. “We have seen an increase in more high-end sales, particularly diamond engagement rings,” he said. “Perhaps people are looking for security in their lives after lockdown and are committing to their partners?”

General manager of Victorian-based jewellery manufacturers Golden Mile Jacinta Collins described this year as “strange, to say the least.”

“Before the first round of lockdowns, we had built up a really good momentum with our customers, and it seemed to be ticking along nicely, until we had to go into lockdown across the country,” she said. “It actually gave us the perfect opportunity to build our new website, and work on things that got pushed aside for so long. “We feel like we have bounded forward in other areas of our business, which has in turn started to pay off for us in sales recently.”

Big-name manufacturer Peter W Beck is taking a broad approach, with Peter stating that all industries appear to be facing a downturn because of the pandemic. “We believe this is mostly due to a lack of consumer confidence,” he said.

Where manufacturers are feeling the hit

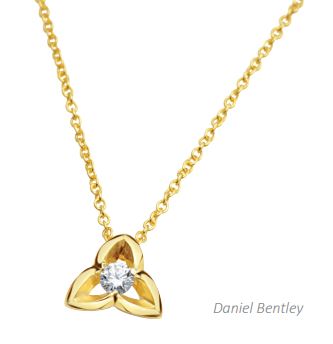

Manufacturers are particularly feeling the pain in doing business when it comes to travel restrictions, border closures and the soaring price of gold. Queensland-based bespoke jeweller Daniel Bentley said that the Victorian lockdowns and the closed state borders put him at a disadvantage because a big percentage of their stockists are closed and the state border restrictions prevents his business from visiting other retailers around the country.

Jacinta also cited regional quarantine periods and travel restrictions as major barriers for Golden Mile, but was also concerned about a major drop in sales come Christmas time compared to previous years. “As jewellery is considered a ‘luxury item’, it’s obviously not going to be high on a lot of people’s lists this Christmas,” she said.

Peter Beck cited low consumer confidence as making business tough, but also went beyond immediate concerns and acknowledged that Australia is in a recession. “Recessions are historically not known for being buoyant trading periods,” he said.

“There has been an initial rush to buy gold jewellery as investment pieces with the increase in gold prices, but I don’t know if that will sustain itself into Christmas trade, with so many people with minimal or low income and no ‘expendable’ income.”

For Roland, it’s the price of gold and silver that’s causing him the biggest headache at Solar Jewellery. “Where retailers may have ordered say 10 rings now it’s five to seven,” he said. “Dollar value sales are up but volume is down.”

Making the most of a bad situation

As Jacinta noted earlier, she and her team at Golden Mile used the lockdowns and downturn as an opportunity to work on her online platform and other neglected parts of her business, and she’s not alone in her method. Brett said that he continues to do the majority of his communication with his Deer Honey Jewellery clients online.

“I am comfortable sharing designs and footage of diamonds and gems with my clients to get the go ahead on a custommade job without the need for them to be face to face,” he said. Chris Worth has adopted a similar approach at Worth & Douglas.

“We have the technology, online presence, and a full sales team allowing us to showcase new product and collaborate more directly with our customers either on the road or remotely,” he said.

Others are using the restricted travel as an opportunity to promote their ability to manufacture locally to potential clients. Peter Beck said they always promoted Peter W Beck with pride as Australian manufacturers. “We believe under the current conditions that being an Australian manufacturer is a key advantage in combating these travel restrictions,” he said.

Master Jeweller Glenn Curtis from Curtis Australia said that his team’s focus is on looking forward and further ahead, developing new and exciting products to fit into specific market segments, to excite and tempt consumers. “These pieces are the result of detailed market research, something we feel retailers and manufacturers should look at more carefully,” he said.

The state and the future of jewellery skills and labour

The future of the jewellery industry has at times also looked uncertain for fears of a future skills shortage. Unlike other major trades such as carpentry, automotive or electrical, jewellery is not on the national skills needs list, and also does not attract anywhere near the level of interest from budding apprentices as their aforementioned competitor trades.

Our respondents had mixed feedback on the topic, with some confident about there being adequate numbers of new jewellers for the future of the industry, while others cited difficulties in finding qualified employees.

Brett said there were still plenty of people interested and wanting to get into the industry, and that the pathways into the trade are changing. “There are more private courses being run such as Peter Keep’s online training; he runs a fantastic resource for new and existing jewellers,” he said. Glenn was also optimistic, reporting that he hasn’t experienced any skills shortages.

“Curtis has a long tradition of training apprentices, many of whom have gone on to represent the state and in one case Australia, at the World Skills Competitions,” he said. “We train our apprentices in conjunction with an industry recognised training program, so they have a highly regarded, professional qualification.” Peter Beck acknowledged that the Australian jewellery industry has for many years found it challenging to attract the right skill level to the manufacturing sector of the industry, but remained optimistic nonetheless.

“Despite these difficulties it is to the industry’s credit that it has displayed not only a willingness, but great enthusiasm to train good people as they become available,” he said. “The manufacturing jewellery industry in Australia has survived for 100+ years and we believe that it will continue to survive into the future.”

The future of training is also looking bright in the land of the long white cloud, with Roland reporting an uptick in apprenticeships in New Zealand in both jewellery and watchmaking. “(We’re) expecting a further increase due to a new COVID inspired government subsidy scheme,” he said.

Jacinta was one of those who have struggled to find qualified jewellers in recent years. “When we’ve looked for new jewellers or manufacturing staff in recent times, it’s generally people who have been in the industry a while, or are of an older generation,” she said.

“When we’ve looked for new jewellers or manufacturing staff in recent times, it’s generally people who have been in the industry a while, or are of an older generation,” she said. “As we have the younger generation of our family coming through the business, getting ready to take over when the time comes, we definitely want to find younger employees that can grow with us and be with the company long-term.” On a similar note, Chris admits that there are not as many jewellery manufacturers as there were 10 years ago, meaning fewer apprentices have been taken on, but said that there are still a lot of students attending jewellery schools.

What your local manufacturing jewellers have to offer

With massively decreased revenue to share around the industry for the rest of the year, it’s become increasingly important for manufacturers to have their unique point of difference to ensure their place in Australian or New Zealand contemporary jewellery remains secure.

Glenn said Curtis Australia is a brand first, and that they offer retailers and consumers a unique range of pieces. “One thing that sets us apart is we feel, our approach to design,” he said. “We tend to create collections with themes, our Myst Collection being a good example of a theme that crosses product categories, and encourages collecting or purchasing more than one piece. “We feel we can offer a great deal to buyers, and a Curtis Collection would enhance their individual store offering.” At Solar Jewellery, Roland highlights that they are the largest manufacturer/wholesaler of New Zealand-made coloured precious and semi-precious stone jewellery in rings, earrings and pendants.

“For the past few years we have been pushing the fact that our range of jewellery is NZ made using NZ-sourced gold,” he said. “This has found a definite niche with retailers particularly independents.” Chris said that Worth & Douglas are jewellery manufacturers who work with a wide array of precious and alternative metals, specialising in wedding rings, engagement rings, and bangles. “We also have expertise in customised designs in these areas which is a popular service,” he said.

“We offer a variety of choices, including engraving, special finishes, and thousands of designs; anything from the classic wedding ring to diamond wedding rings.” Daniel Bentley’s jewellery has always been contemporary, and Daniel said it draws inspiration from Scandinavian design and Australian nature. “Our jewellery has always had its own unique style and every piece tells a story,” he said.

“We are a boutique jewellery brand which gives our stockists a way to differentiate themselves from other jewellery stores.”

Golden Mile and Peter W Beck are large-scale manufacturers who offer contemporary pieces made to any size, colour or quantity. Jacinta said that Golden Mile are always looking at new designs based on trends, to try to make sure they’re always carrying something new and relevant.

“There aren’t many large-scale manufacturers left anymore, as they all have their own niche range of products, where as we are a ‘one stop shop’ for a huge variety of gold jewellery,” she said. Peter said Peter W Beck offers a very broad product range in precious metal refining, casting, precious metals for the manufacturing jeweller, plus rings and other jewellery products for the jewellery industry. He said that Peter W Beck are not producers of fashion jewellery, and as such, their range is both contemporary and perennial. “Our jewellery is set apart by our attention to design elegance and high production quality,” he said.

As a trade jeweller, Brett said that he tries to keep each design made at Deer Honey Jewellery unique, even if it is a more classic design. “I certainly keep an eye on international trends,” he said. “Fancy shapes and colour gemstones are always going to be my favourite to work with.”

Further Reading on Australian Manufacturing: