In the last few years, the design and print department at Palloys has seen great changes in the type of jobs the team is working on. Jewellers, jewellery designers and artisans alike are seizing the advantages computeraided design brings. Manufacturing software is witnessing a surprising new trend. One our team didn’t even see coming…traditional hand-carvers bringing their unparalleled skills to the virtual world.

Closing the loop

We all know jewellers and jewellery designers have been utilising computer-aided design software for years, both to aid their creative ideas as well as increase volume production and save time. The Palloys team is now seeing an increase in traditional artists also using our technological services, closing the loop between the artisanal world and the virtual world of CAD and CAM innovations.

An artisan traditionally spends anything from several hours to days carving one design into their chosen material. This material may vary from stone to wax to other organics such as shell or even wood. An artisan usually prefers these types of materials as they provide a solid tactile feedback mechanism, allowing them to leverage years of muscle memory into a medium they truly enjoy working with, producing fantastic results. Though, the transition of these skills to the CAD and CAM world by some hand carvers has not always been a smooth and successful one.

The most important aspect of their work human touch – the artisan’s most valuable asset, has been lost. The artisan may also need to rely on outside assistance to bring their product into creation, introducing interpretation and communication issues to the outcome. It is understandable the loop has been open for so long.

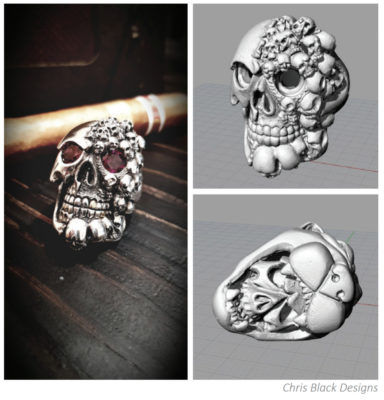

Palloys is witnessing a shift in the creation process. Our team is seeing traditional hand carvers now producing most, or even all, of their shapes usually at 1.5 to 2 times the intended scale. Hand carvers send their scaled design to be 3D scanned and returned as a silver cast, which they can tool to completion. The final design is returned once more to be scanned a second time, reducing to real scale to its intended size. Following this process, the design is permanently digitised, allowing it to be further manipulated into unlimited options in size, material and overall design truly extending the artisan’s creativity and opening up opportunities such as turning a pendant scan into earrings, a ring and even cuff components.

Innovation supports tradition

In previous years, this “loophole” would have involved making a physical mould in which further work could be done but always at the same scale. The closing of the loop between the physical and virtual world is seeing a resurgence in artisanal hand carving.

CAD software has and is continuing to empower artists to create some truly innovative and creative works. Innovation allows traditional artisans to complete work or portions of their work more quickly and easily, eliminating unnecessary errors. In some branches of the arts, including custom jewellery design, CAD is now an integral part of the creative process.

The design and print team at Palloys is one of the largest and most experienced in the world. The highly skilled Palloys Design team is proficient in all major computer-aided design (CAD) programmes and is very happy to help artisans further with this kind of work. Our team is supported by an unmatched 3D printing capacity, proudly producing the highest resolution in the industry.

Computer-aided design has greatly influenced the world of art, and we look forward to seeing more and more creative designs both in jewellery and art as the software continues to innovate. The Palloys Design & Print team will work with you to sustain the creativity of your design. Speak directly with the team in your My Palloys account at www.palloys.com/create